Introduction

“Digital dentistry” is any dental technology or device that incorporates digital or computer-controlled components.

The introduction of digital imaging led to the development of three-dimensional (3D) models and the manufacturing of dental prosthesis. 3D medical modeling began in about 2000 and has now exploded with the advent of 3D printers.

Some examples of digital dentistry include:

- Digital radiographs

- CAD/CAM (computer aided design/computer aided manufacturing)

- Computer-guided dental implant surgery

In the field of oral and maxillofacial surgery, this has revolutionized our specialty. Digital medical modeling has benefited both patients and the surgeon. We can now:

- Precisely plan surgeries on the computer

- Visualize the results

- Identify challenges that may arise during the procedure

- Use 3D guides, or templates, to ensure accuracy during surgery

How Digital Dental Surgery Works

We begin by taking a CT scan of the patient. Dental CT scans or Conebeam CT scans give a high level of detail with much lower radiation than a medical CT scan. The digital images are sent to a medical modeling company that uses CAD/CAM software and a 3D printer to produce a plastic guide. The surgeon uses this guide to precisely plan his work. For example:

- To position dental implants

- To re-position jaws for jaw surgery

The surgical procedure is faster, more accurate and often less painful than traditional methods. However, there are limitations. Minor inaccuracies in positioning the guide can be an issue during implant surgery, if there are no teeth to act as a guide. However, the inaccuracies are in the range of 1.00-1.65 mm (Turbush et. al., 2012), which is considered acceptable for the procedure.

Case Studies

Complex jaw surgery and dental implants can now be planned and executed entirely digitally with just a CT scan. The case shown here shows a complex 3D disfigurement of the patient’s jaws (Figure 1). The upper jaw and lower jaw do not align and are asymmetrical.

Complex jaw surgery and dental implants can now be planned and executed entirely digitally with just a CT scan. The case shown here shows a complex 3D disfigurement of the patient’s jaws (Figure 1). The upper jaw and lower jaw do not align and are asymmetrical.

Using CT scans and computer-guided 3D surgical planning, we were able to see the precise amount of rotation that existed within in three planes of space.

Based on this information, we manipulated the segments on the computer to make them perfectly align. We created a 3D surgical guide from this plan.

In the operating room, the jaws were mobilized with bony cuts and positioned using the guide in the corrected position.

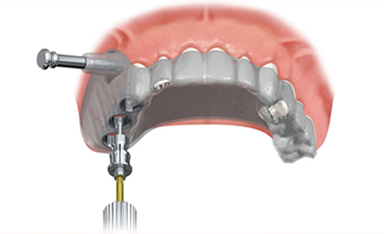

The second image shows a computer-guided implant placement.

The second image shows a computer-guided implant placement.

In this case, the implants were first planned first on the 3D CT scan. This information was sent for fabrication of a plastic guide. The guide was made to the specifications we provided, based on the imaging, where we wanted the final teeth to be placed, and how we wanted the teeth to look.

This method allows us to avoid damage to important structures (nerves and blood vessels), and to choose the proper size and angulation of dental implants.

The third image shows a digital rendering of the final surgical solution.

The third image shows a digital rendering of the final surgical solution.

3D Modeling is Revolutionizing All Surgical Specialties

3D medical modeling has revolutionized the surgical field for all specialties. The technology is now being used to print artificial body parts and metallic medical devices that are implanted, such as custom joint replacements. We are able to order an exact replica of the body part that needs to be replaced or corrected, and we can design the new part to perfection.

What’s next? Tissue engineers at Harvard University have recently used a bio material to create a 3D print of a network of capillaries. This brings us one step closer to organ fabrication.

At Argyle associates, we have the technology and expertise to provide our patients with a complete digital solution.